New Year's Day|Shandong Hengliyuan New Energy Co.,Ltd.

2025-02-11

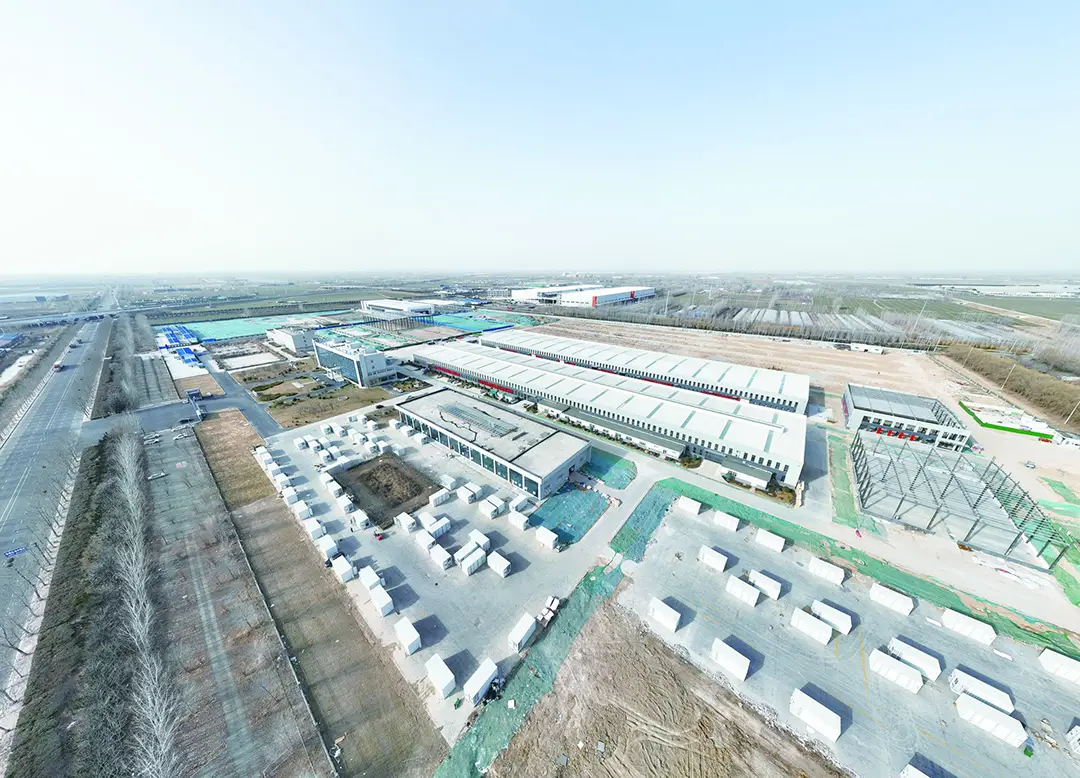

Early in the morning of February 5, located in Qihe Economic Development Zone, Shandong Hengliyuan New Energy Co.,Ltd. The production line of the mechanical arm of high-frequency swing, laser welding equipment in the green light behind the glass window flashes, forklifts in the aisles between the shuttle delivery of materials - there are no firecrackers here, but played a song of the “war for spring” of the industrial music.

Shandong Hengliyuan New Energy Co., Ltd (hereinafter referred to as Hengliyuan) is a new energy science and technology enterprise focusing on lithium industry chain, with wind, light, storage and multi-energy collection application as the core business. The company has the R&D and manufacturing capacity of battery module, inverter system and energy storage system, and has four enterprises under its banner, including Inner Mongolia Zhongke Hengyuan, Inner Mongolia Zhonghe New Material, Shenzhen Lanshan New Energy and Shandong Dehong Electric Power Engineering, which cover the key cathode materials of lithium batteries, electric cores, Battery Management System (BMS), Energy Management System (EMS), Energy Storage Inverter (PCS) and other multi-energy complementary system integration, and so on. It has realized the whole chain industrial layout. The company's products are widely used in electric power, transportation, industry and commerce, household and other fields, and are exported to Germany, Italy, Switzerland, South Africa and other more than 20 countries and regions.

“We just delivered a batch of orders for 200 MW photovoltaic distribution and storage projects before the Spring Festival, and now we are rushing to make the next batch of large orders from customers.” Zhang Zhikai, deputy general manager of Hengliyuan, introduced, “The orders before the year were scheduled until June this year, and we received many new customers' intention orders just after the start of work after the New Year, and we are working overtime to catch up with the orders.”

The market is hot from the technology breakthrough. Walking into the 26,000 square meters of intelligent workshop of Hengliyuan, “technological paradigm” comes to the surface. In the electric core stacking station, four extrusion table is running in alternating mode of AB surface, the mechanical arm will quickly put the electric core into a neat array. “In the past, by manual stacking, error is big, low efficiency, now full automation production, not only the precision is improved, the daily capacity of a single production line has also increased by three times.” Technician Cui Yanjun pointed to several mechanical arms that are working at full speed to put the cores.

In the laser welding area, six 6KW ring spot welding equipments are shooting out silver sparks. Compared with traditional welding, the company is equipped with laser liquid cooling system and nitrogen protection device, which can effectively prevent oxidization, improve the welding effect, and ensure that the products are firmly and reliably connected.

“Judging the product is good or bad, the testing link is essential.” Zhang Zhikai introduced, at the end of the production line is the lithium battery production line test, box assembly, air tightness test three links. In the final test, workers will test the core module and the entire liquid-cooled box for ambient temperature, total pressure internal resistance, insulation withstand voltage, airtightness and other key indicators to strictly control product quality. At the same time, the energy management system will synchronize and upload more than 200 parameters of each battery, such as voltage and internal resistance, to the cloud, and once an abnormality is detected, an alarm will sound immediately.

“Our company has created a 'core-PACK-system' whole chain layout, which reduces the cost of energy storage kWh by 18%. The self-developed stacked household energy storage system can monitor the charging and discharging status in real time through cell phone APP.” Zhang Zhikai introduced, during this year's Spring Festival, the company only energy storage product sales hit 300 million yuan sales.

It is understood that the constant source of the company will be based on market conditions to build the second phase of the core manufacturing project, while increasing investment in research and development of technology, self-built new energy research institute, and Shandong University, Soochow University and other cooperation, to set up a joint innovation center of green energy. After the project is fully completed and put into use, it can realize the annual output value of about 6 billion yuan, and pay taxes of about 360 million yuan.